Features Overview

Company Data

Dunbroze Precision, established in 2018, is a family owned and operated business with 14 years of combined machining experience! We are always looking for ways to improve and explore new avenues.

➢ DUNS: 075020501 ➢ CAGE Code: ***** ➢ NAICS CODES: ○ 332710 - Machine Shops

The ability to operate around the clock allows us to provide customers with flexible lead times. Using the latest in CNC technology with our 2018 and newer models of CNC machines opens new opportunities for exceptional quality at a competitive price.

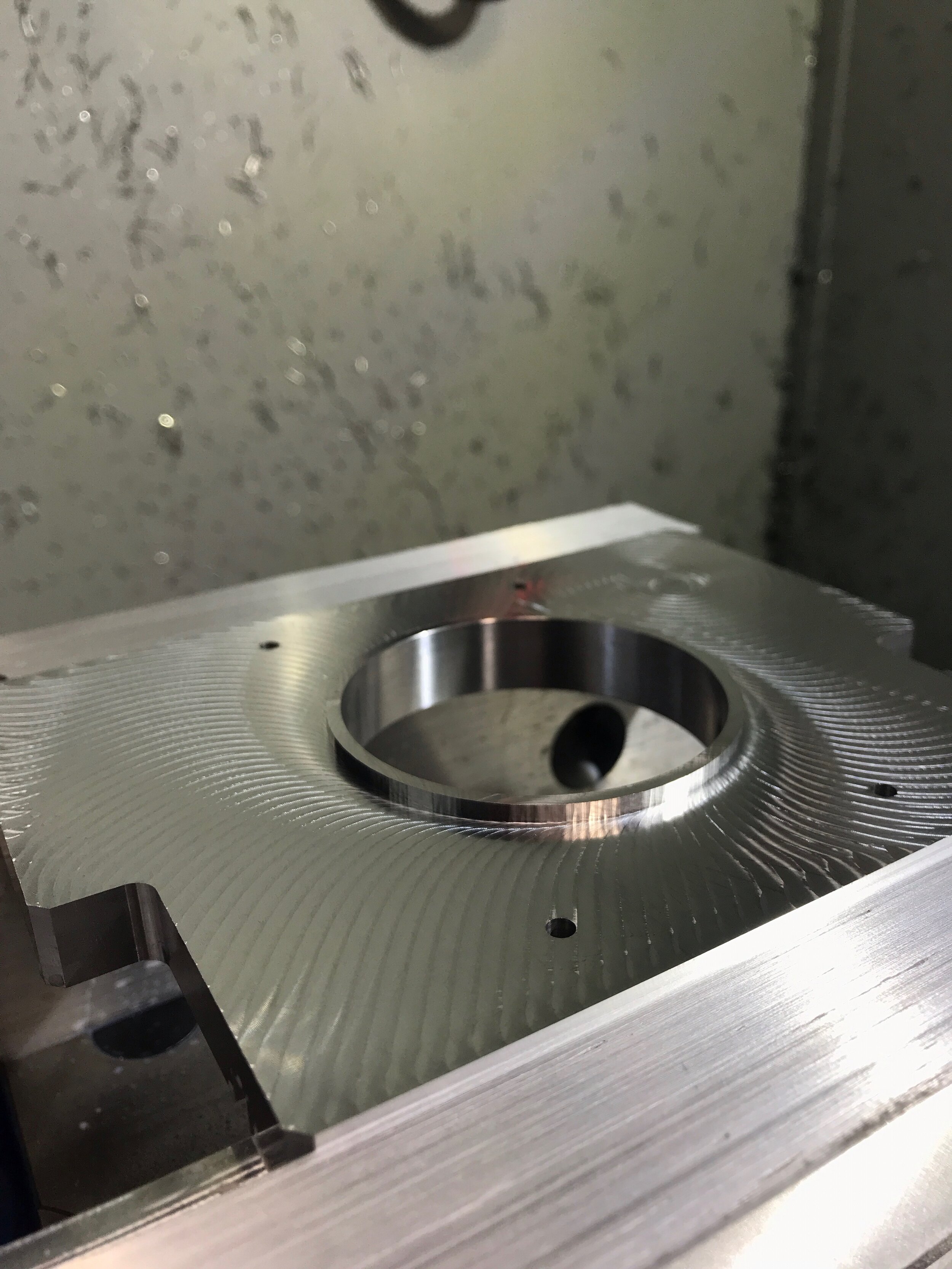

2019 HAAS Automation VF-2 V.M.c.

This HAAS milling center is equipped with all-new manufacturing technology to ensure the most efficient machining processes, which lead to faster cycles and shorter lead times. Some of these key features listed below enhance the manufacturing experience as well as provide incredible part quality from tight-tolerance dimensions to exceptional surface finishes.

10,000 rpm spindle (Ideal for high-efficiency milling applications)

Renishaw Probing System (Faster Set-Up times with exceptional accuracy)

High-Speed Machining (Feed and Rapid rates up to 600 in/min)

Rigid Tapping (Eliminates external “hand-tapping” of threads)

30”x16”x20” Travel Limits.

2018 haas automation mini-mill v.m.c.

This HAAS milling center is equipped with all of the same key features as the VF-2, with slight differences which are listed below. This machine is ideal for prototypes and smaller jobs, while still running efficiently and accurately.

10,000 rpm spindle (Ideal for high-efficiency milling applications)

Renishaw Probing System (Faster Set-Up times with exceptional accuracy)

High-Speed Machining (Feed and Rapid rates up to 500 in/min)

Rigid Tapping (Eliminates external “hand-tapping” of threads)

16”x12”x10” Travel Limits.

2020 HAAS AUTOMATION ST10 LATHE

This HAAS turning center is equipped with many key features to ensure extreme efficiency, quality, and precision with every part that goes in the spindle!

15hp/6,000 rpm spindle (Beyond efficient turning speeds!)

1,200 in/min (Exceptional feedrate capabilities for high efficiency turning to supply customers with lightning fast leadtimes)

Automatic Tool Presetter (Provides fractional set-up time on parts, resulting in extremely accurate, cost-efficient cycles.)

Equipped Parts Catcher (Ensures every part is safe and sound after every cut-off cycle, maintaining industry leading quality on our finished parts)

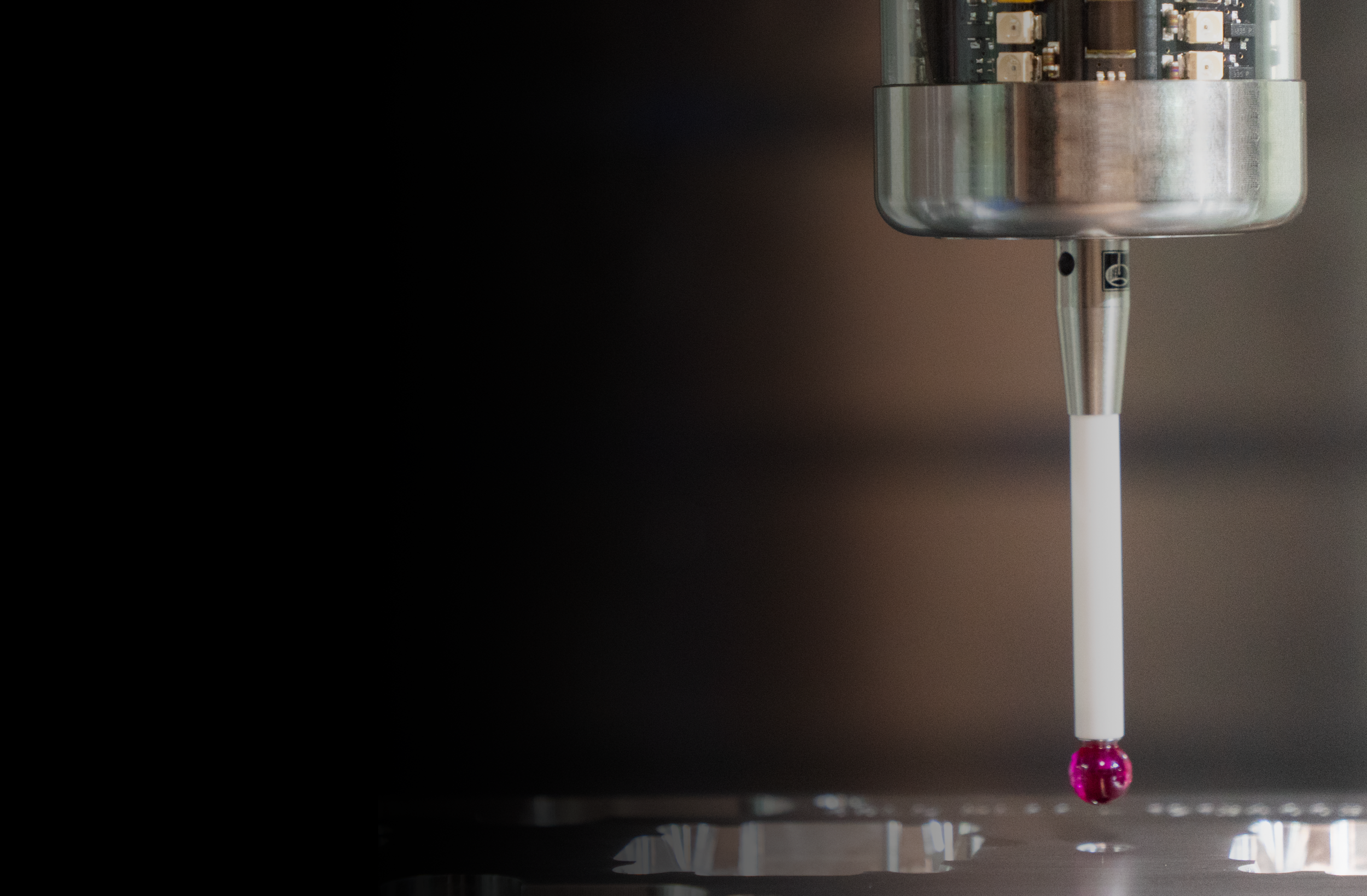

2019 Tesa-hite 400

Our Quality Control department is equipped with all new tools including our latest addition, The TESA-hite 400 inspection device. Accurate up to +/-.0001”. This tool is accompanied by a precision ground and leveled granite inspection table, ensuring the most accurate measurements possible for almost all applications. In addition, we also have a full stock of new pin gages, angle/radius gages, micrometers and calipers. We also have the ability to stock any high-tolerance, certified pin gages for special applications if necessary.

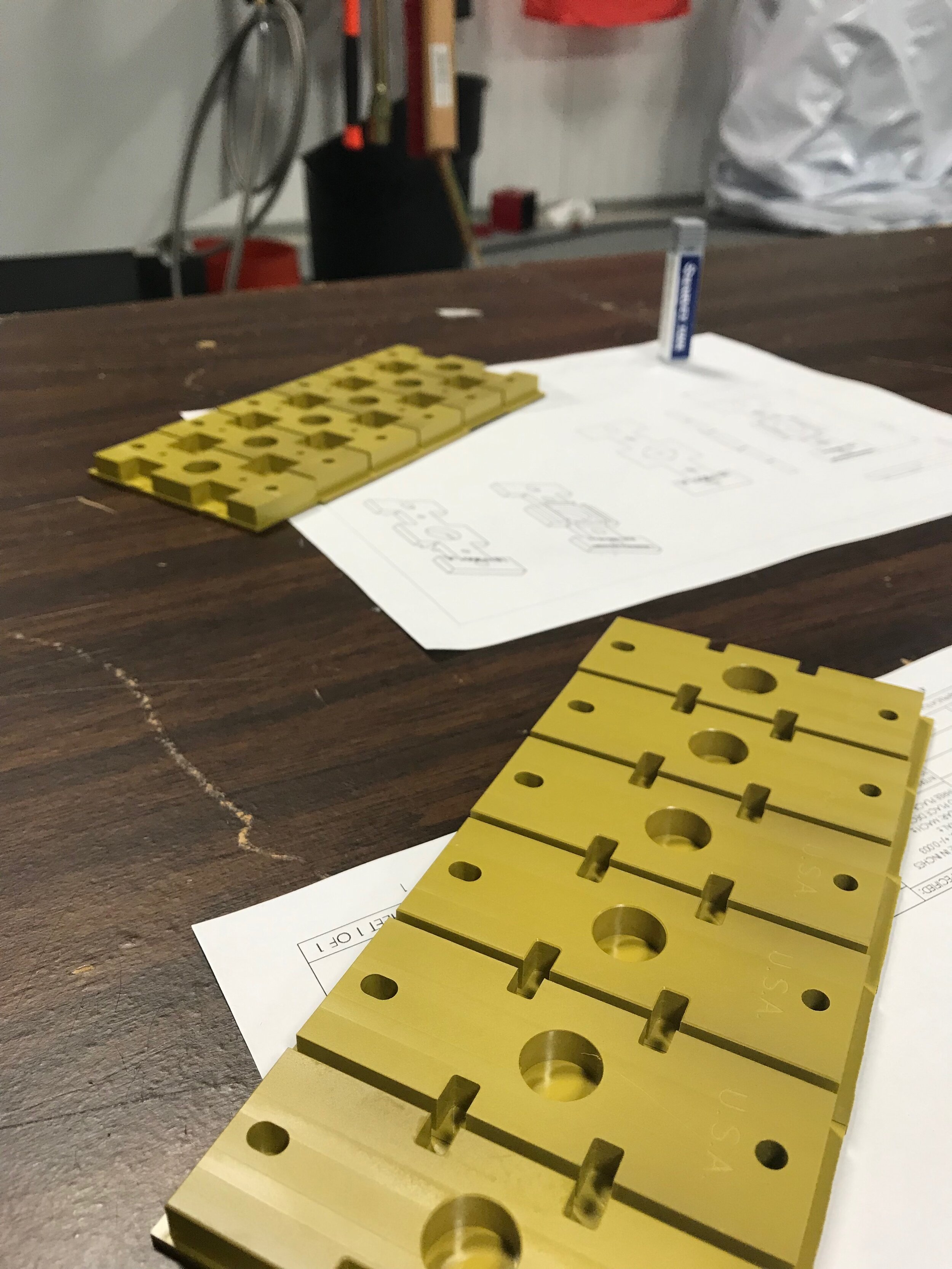

The Dunbroze Team strives for greatness in all aspects of our manufacturing processes, ranging from customer service, to unmatched quality, performance and delivery on all orders that come through the door. We are constantly forming relationships with suppliers to ensure our tooling and plating services are of extreme caliber, making sure every part is completed beyond expectations.

Whatever it is, the way you tell your story online can make all the difference.